Trends

Trends

Europe’s manufacturing industry is undergoing a significant shift right now. A new wave of regulations focused on sustainability, such as the Ecodesign for Sustainable Products Regulation (ESPR), is reshaping market expectations and legal requirements to build a circular economy.

If you’re a manufacturer or product supplier in the EU market, understanding ESPR properly can be the “make or break” factor for your business.

What is ESPR and Why Does it Matter for EU Manufacturers?

The Ecodesign for Sustainable Products Regulation (ESPR) is an EU-proposed regulatory framework aimed at making sustainable products the standard across all industries that are either operating in or exporting to the EU.

ESPR aims to achieve this by redefining how products are designed, manufactured, documented, and managed after the product’s end-of-life, to combat negative environmental impacts throughout a product’s entire lifecycle, and beyond.

ESPR builds on and replaces the older Ecodesign Directive (2009/125/EC). However, unlike the Ecodesign Directive (2009/125/EC), ESPR focuses beyond energy efficiency to focus on:

- Durability

- Repairability

- Recyclability

- Recycled content

- Reduction of hazardous substances

If you’re a manufacturer, an Operations Manager, or a Sustainability Manager, ESPR directly impacts your business in the following ways:

- Product design and production process must now meet the new circular economy standards

- Supply chains must provide transparent, traceable data

- Regulatory oversight will increase over time, with penalties for non-compliance, which can potentially lead to losing access to the EU market entirely.

Adhering to ESPR is not optional; ignoring ESPR can risk your business falling behind competitors, or even risking your entire business.

This guide aims to assist EU manufacturers in navigating the new landscape. You will gain a foundational understanding of ESPR, learn how Digital Product Passports (DPPs) are connected to ESPR compliance, and receive a comprehensive overview of the core requirements. Additionally, you will get a glimpse of the implementation timeline and an outline of the first steps you can take to keep up with the new regulations.

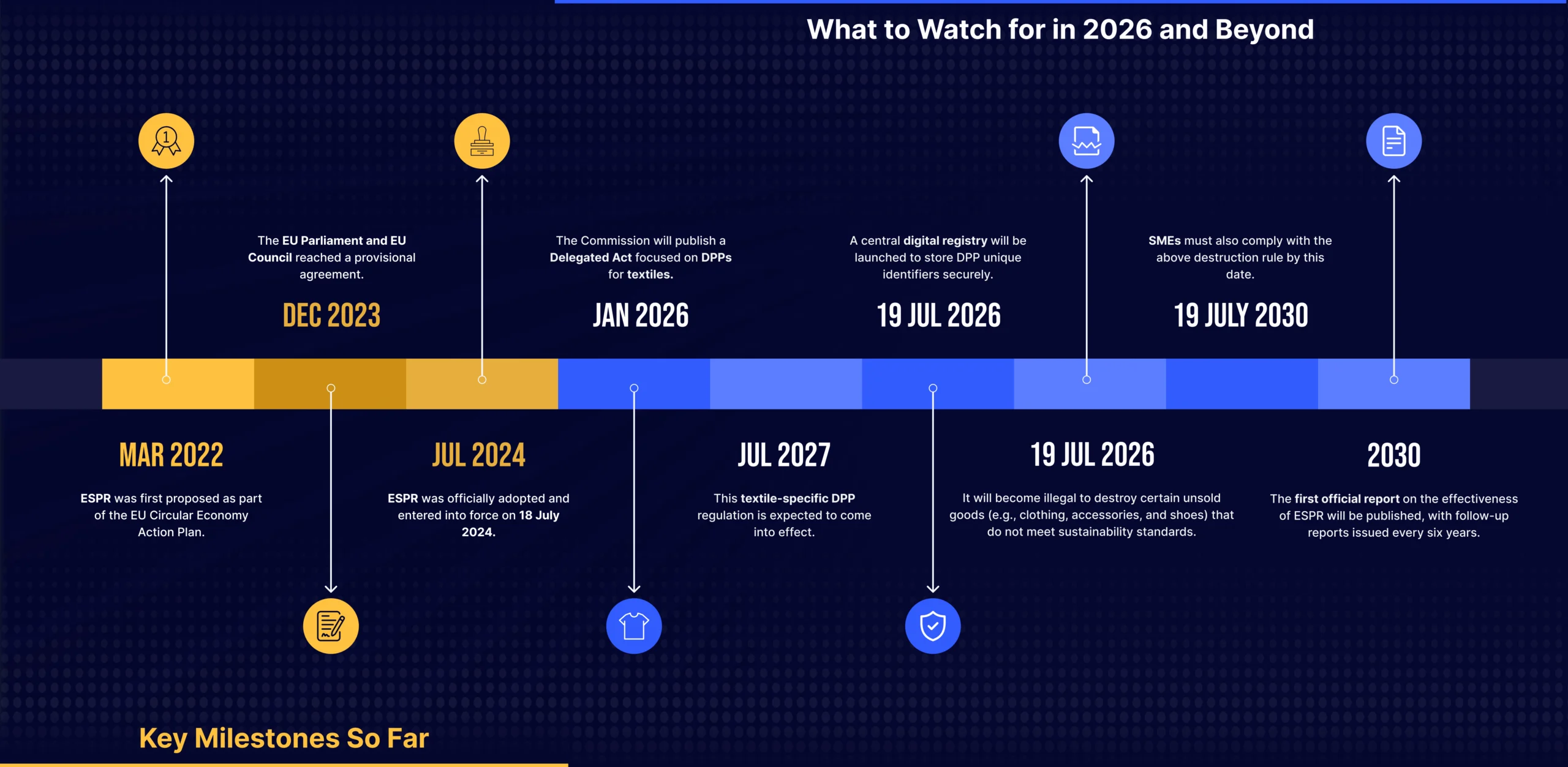

The ESPR Timeline: When Can We See it in Full Effect?

The Ecodesign for Sustainable Products Regulation (ESPR) is a result of years of research, and now it’s here. If you want to plan your next moves to keep up with this regulation, you must understand the timeline of how and when its rolling out.

“The earlier you understand ESPR’s timeline, the better you can prepare for what’s coming.”

As we can see from this timeline, ESPR is here to stay, and it’s growing. And that’s why, if you’re a manufacturer or a supplier operating in the EU, you must focus on early preparation and flexibility if you want to stay competitive and compliant in the EU Market.

Digital Product Passport – The Backbone for ESPR Compliance

The Digital Product Passport (DPP) is the digital backbone of the ESPR framework. In the simplest terms, a Digital Product Passport is a structured, electronically stored dataset tied to a specific product or a product batch that holds information about its sustainability, circularity, and compliance characteristics.

How is DPP Connected with ESPR?

Digital Product Passport (DPP) is the core component for complying with the ESPR. As a manufacturer in the EU market, you must understand how DPPs fit into the equation for complying with the ESPR.

ESPR: The Rulebook

The Ecodesign for Sustainable Products Regulation (ESPR) is the overall set of rules that sets clear objectives and legal obligations for manufacturing sustainable products in the EU.

ESPR enables the European Commission to set specific requirements for product categories with the help of legal tools called Delegated Acts.

ESPR aims to guarantee that every manufactured product in the EU is:

- More durable and reliable in the long run

- Improved to be reused and upgraded easily

- Repair-friendly and easier to maintain

- More energy and resource efficient

- Manufactured with more recycled content

- Free from chemicals that can be a threat to circularity

DPP: The Information Carrier

ESPR requires a product to provide complete, transparent data during every stage of its lifecycle, and the Digital Product Passport is the practical tool for it.

DPPs are not just a one-size-fits-all document or a static label – it’s a secure, structured electronic dataset that is uniquely linked to a single product or a batch of products.

Fundamentally, a DPP’s goal is to give easily available and trustworthy information to multiple stakeholders:

- Consumers can make informed purchasing decisions based on verifiable sustainability credentials.

- Businesses can facilitate repair, refurbishment, and recycling through crucial information (e.g., disassembly guides, material composition, etc.).

- Regulators can easily verify whether a product complies with ESPR standards.

Understanding and meeting ESPR’s requirements for Digital Product Passport is critical, as DPPs are the most visible and practical aspect of an EU manufacturer’s ESPR compliance.

Delegated Acts: Turning Principles into Product-Specific Rules

While the Ecodesign for Sustainable Products Regulation (ESPR) establishes the overarching goals, the detailed, legally binding eco-design requirements for specific individual product categories (such as textiles, furniture, electronics, etc.) will be documented in individual Delegated Acts.

These Delegated Acts are crucial for EU Businesses and Manufacturers. Delegated Acts are binding legal instruments. They outline the requirements for each product category, making them the essential tool for compliance planning.

Each Delegated Act will define:

- The Ecodesign parameters for the product category (e.g. minimum recycled content, repairability benchmarks)

- The exact data points required in the Digital Product Passport (DPP)

- The compliance deadlines for implementation

- Any sector-specific exemptions or specific conditions

Manufacturers must actively monitor the development and the EU Commission’s publication of Delegated Acts relevant to their product lines. These Delegated Acts are your roadmaps to ESPR compliance.

Data Carrier & Unique Identifier: Your Product’s Digital Access Key

How can someone access the DPP information linked to a physical product? ESPR has thought of this too.

ESPR requires a data carrier on each product, or its packaging, or within accompanying documents. Some common data carriers that can be used include:

- QR Code

- RFID Tag

- NFC Chip

- Data Matrix Code

These carriers will link to a unique identifier, connecting the product unit, batch, or model to its corresponding Digital Product Passports. This ensures that everyone, from consumers to regulators, can access accurate, real-time product information at any given time.

Delegated Acts will also define the technical format and placement of these carriers. Scanning the data carrier lets stakeholders access the corresponding DPP data electronically. These elements create the essential bridge between the physical product and its digital twin.

Key ESPR Requirements Impacting Your DPP Generation

Understanding ESPR’s core requirements is the first step for developing a compliant Digital Product Passport. Here are the key ESPR requirements that’ll impact your DPP generation:

1. Scope and Timelines: When Does ESPR Apply to My Products?

Some of the common questions manufacturers often ask:

“Does ESPR apply to my product now?”

“Do I need to comply now?”

To put it simply, the answer to both these questions is: “It depends”.

The EU is rolling out ESPR in phases, prioritising product groups based on their environmental impact and the potential for sustainability improvements through Ecodesign.

The European Commission has identified priority product groups, as well as sustainability requirements based on environmental impact, market relevance, policy gaps, and strategic value. The priority product groups include:

- Final Products:

- Textiles & Footwear

- Furniture

- Tyres

- Mattresses

- Detergents

- Paints & Varnishes

- Lubricants

- Cosmetics

- Toys

- Fishing Gear

- Absorbent Hygiene Products

- Immediate Products:

- Iron & Steel

- Commodity Chemicals

- Non-ferrous (excl. aluminium) Metals

- Aluminium

- Plastics & Polymers

- Pulp & Paper

- Glass

These products must follow the Horizontal Sustainability Requirements:

- Durability

- Recyclability

- Recycled Content

Each product group will receive its own compliance timeline, outlined by its corresponding Delegated Act.

As a manufacturer or supplier operating in the EU, staying updated with every new change is the key. Proactively keep track of the EU Commission’s work plan and sector-related publications, so you can stay prepared at all times.

Because, as we have already discussed, the scope of ESPR is rapidly growing. Products that are not already covered under ESPR today could very well be added to the next iteration.

2. Data Requirements: What information must be Included In the DPP?

One of the ESPR’s biggest impacts on manufacturers’ data management practices was arguably the ESPR Data Requirements.

A Digital Product Passport goes far beyond the technical specifications we currently find on product labels or datasheets.

ESPR demands deep transparency throughout the product’s lifecycle. While the exact data requirements list will be finalised for each product category in their respective Delegated Acts, the fundamental types of information we expect to be in the list are:

- General Product & Manufacturer Information:

- Unique product identifiers (model, batch, serial numbers as applicable).

- Name, address, and contact details of the manufacturer.

- Manufacturing location (potentially).

- Standards and certifications

- Applicable standards and certifications (if applicable).

- Sustainability & Environmental Performance Data:

- Information on energy consumption and efficiency.

- Water consumption during the use phase (if relevant).

- Carbon footprint data (potentially aligned with EU PEFCR methods).

- Resource efficiency metrics.

- Release of microplastics (especially relevant for textiles).

- Recycled content percentage (both pre-consumer and post-consumer).

- Circularity Information:

- Material composition (including percentages, especially for key/critical materials).

- Information on durability and reliability (e.g., expected lifespan, warranty).

- Repairability information (e.g., availability of spare parts, repair manuals, diagnostic tools, repairability score if applicable).

- Detailed disassembly instructions for repair and end-of-life treatment.

- Information facilitating reuse and refurbishment.

- Supply Chain Transparency:

- Information on the origin of certain raw materials (especially critical ones).

- Potentially, information related to supply chain due diligence (as seen in the Battery Regulation).

- Compliance & Safety Information:

- Declaration of conformity.

- Presence of Substances of Concern (SoCs) above certain thresholds (potentially linking to REACH/SCIP database requirements).

- Safety instructions.

As you can see, the challenge here is not a small one. If you’re like most manufacturers, much of the information needed for an ESPR-compliant Digital Product Passport (DPP) is most likely scattered across different departments, lost within supply chains, or probably not collected in a structured way at all.

If you want to be properly prepared for ESPR, you have to start by setting up strong internal systems to source, collect, verify, manage, and organise this complex and detailed data.

The challenge doesn’t stop there! As standardised reporting formats are still evolving, it means to stay ahead, flexibility and forward planning are the key.

Meeting ESPR demands will not happen by accident; it calls for a carefully considered data governance strategy that brings your product, supply chain, and compliance data together into a single, trusted source of truth.

3. Technical Aspects: How Will the DPP Be Accessed?

To meet the requirements of the Ecodesign for Sustainable Products Regulation (ESPR), manufacturers must make sure that the Digital Product Passport (DPP) can be accessed through electronic means quickly and easily.

You can achieve this with a few essential technical elements working together:

- Unique Identifier: Each model, batch, or product will have a unique digital code known as a Unique Identifier. The product’s digital passport can be unlocked using this code.

- Data Carrier: You’ll need a Data Carrier to link your physical product with its digital record. Machine-readable codes, such as QR codes or Data Matrix, can get the job done. You can also use built-in devices like RFID or NFC tags.

The right choice, of course, depends on your product’s type, its value, the operating environment, and any future standards defined in the Delegated Acts or projects like GS1 and CIRPASS.

- Data Platform/Registry: Finally, the DPP’s data itself must be stored on a Data Platform or Registry. You can manage this system in-house, partner with a trusted third-party, or eventually link to a centralised EU platform or a decentralised network (both of these options are still being discussed at EU level).

Whatever the case, your platform must prioritise:

- Data security

- Ease of access

- Interoperability

- Long-term data availability

Building this technical backbone is no simple task. You have to design it to be flexible, secure, and future-proof, keeping pace with changing standards while at the same time maintaining full ESPR compliance.

4. Data Verification, Security & Access: Who Gets to See What?

When it comes to the Digital Product Passport (DPP), trust is everything. The Ecodesign for Sustainable Products Regulation (ESPR) sets these clear expectations to make sure that the data behind each passport is reliable, secure, and shared appropriately:

- Data Verification: Firstly, you are responsible for Data Verification.

This means you will need strong internal checks to validate the information you create, and processes to verify any data supplied by third parties. Regulators, known as market surveillance authorities, will also have the power to cross-check DPP data directly against the physical product.

- Data Security: Next, Data Security becomes critical. The DPP may contain commercially sensitive information, so you must put strong cybersecurity measures in place. Preventing unauthorised access or data leaks is not just about protecting your business—it’s a core part of meeting ESPR obligations.

- Granular Access Control: Finally, the Granular Access Control. ESPR clearly states that not every stakeholder needs to see every piece of data. Access must be tailored depending on who is requesting it:

- Public/Consumers will see a high level of sustainability and repair information

- Repairers/Remanufacturers will get the technical stuff, such as disassembly guides, spare part data, etc.

- Recyclers will get detailed material breakdowns to support safe recycling processes

- Authorities will have full compliance documentation when needed for regulatory checks.

The exact access level rules will be defined in the future Delegated Acts.

However, as a manufacturer, you should start your preparations now. You can build systems that will ensure data accuracy, data protection, and manage complex, role-based access. This will take your ESPR strategy to the next level.

Industry Focus: How ESPR Varies Across Sectors

One important thing to remember is that ESPR is not a one-size-fits-all rulebook.

Yes, the main goals and the framework will stay consistent, but specific eco-design requirements and DPP data points will vary depending on industries.

ESPR will enforce the changes through Delegated Acts. It contains sector-specific rules, deadlines, and compliance details.

Let’s get a clear picture of how it works in practice with some practical examples:

Example 1: Batteries

The EU Battery Regulation (Regulation (EU) 2023/1542) is already working on ESPR requirements in the battery industry.

From 2027, certain battery types, namely light means of transport (LMT) batteries, industrial batteries over 2 kWh, and electric vehicle (EV) batteries, must have a fully detailed Battery Passport, a specialised form of the DPP.

This Battery Passport must include:

- Manufacturer details

- Full battery composition (critical raw materials and hazardous substances)

- Carbon footprint declaration

- Recycled content declaration

- Performance and durability information

- Supply chain due diligence records

- A QR code for easy data access

If you are a battery manufacturer, understanding the connection between the Battery Regulation and ESPR is a must for your business’s future compliance.

Example 2: Textiles

The Delegated Act for textiles is still under development, expected to come into force in 2026, but early discussions and impact studies hint at several likely DPP requirements:

- Fibre composition, including recycled content

- Presence of hazardous chemicals (linked to REACH regulation)

- Microplastic release information (especially after washing)

- Durability measures (e.g., washing resistance, colour fastness)

- Data to support sorting for reuse and recycling

- Repairability details to extend product life

As a manufacturer in the textile industry, it’s best that you monitor these developments closely as of now so you can stay ahead of both compliance requirements and market expectations.

The key takeaway is that, as a manufacturer, you have to focus on the Delegated Acts that are specific to your product category. These acts will tell you exactly what information you need to collect, how you should share it, and when you have to be fully compliant.

You can stay updated by following announcements from the European Commission. You should also actively engage with industry associations, as they often provide early guidance and practical insights for your sector.

Preparing for ESPR: Foundational Steps for Manufacturers

While you may not have the final Delegated Acts for your specific industry yet, that does not mean you can afford to do nothing and wait.

The main challenge of ESPR compliance revolves around data collection and system readiness, making early preparations vital for your future success.

“Laying the groundwork now gives you a huge advantage when compliance deadlines arrive.”

Here are some steps you can start taking today:

- Assess Your Current State

You need to have a clear understanding of your current situation before moving forward. Here’s what you can do for it:

Product Scope Analysis

- Find out which of your products are most likely to fall within the early phases of ESPR based on current EU Priorities.

- Prioritise the product categories that are at most risk.

Data Mapping and Gap Analysis

- Conduct a full audit of your existing data related to sustainability, circularity, and supply chains.

- Ask yourself:

- What ESPR-relevant data do we already collect systematically?

- Where is this information stored? (e.g. ERP systems, PLM tools, supplier portals, spreadsheets)

- Is this data reliable, accessible, and adheres to the required standard?

- What major gaps exist compared to anticipated ESPR requirements?

System Evaluation

- Review your existing IT infrastructure:

- Can your ERP, PLM, MES, and quality management systems manage the deeper levels of data now required?

- Can your current systems handle the assignment and management of millions of unique IDs, and tie them seamlessly into a working Digital Product Passport (DPP)?

How easily can your systems connect and integrate with new platforms as standards evolve?

- Develop a Strong Data Strategy

Once you have a clear idea of where the gaps are, your next step is to plan how to close them.

You can start by creating a practical Data Collection Plan using the following method:

- Take a closer look at your gap analysis and identify the missing information.

- Set up a plan to gather the necessary data. This could include:

- Improving how you internally collect data, making sure information is captured in a consistent and usable way.

- Reaching out to suppliers with structured data requests, which might mean updating existing contracts or adjusting your supplier portals to match ESPR requirements.

Data Validation and Governance

- Set up strict processes for verifying all collected data, whether it comes from internal teams or external partners.

- Assign clear ownership for ESPR data governance within your organisation to avoid confusion later on.

Data Management Approach

- Think about how you will store, structure, secure, and maintain the data over the long term.

- Keep future DPP compliance requirements front of mind when designing your storage and management systems.

“The quality of your data today will decide the strength of your ESPR compliance tomorrow.”

- Foster Internal Collaboration

Preparing for ESPR compliance and DPP implementation heavily relies on teamwork.

It’s not just another responsibility for the IT and sustainability teams, but rather a shared responsibility across your entire organisation.

“Breaking down silos today will make compliance much easier tomorrow.”

Here’s how your internal teams can help drive overall compliance:

- The Sustainability team should interpret ESPR requirements and shape the organisation’s sustainability strategy.

- The Operations and Manufacturing teams are responsible for providing accurate, real-world production data.

- The Product Development and R&D teams must design products that fully embrace eco-design principles.

- The Procurement and Supply Chain teams play a key role in collecting supplier data and making sure upstream partners meet compliance standards.

- The IT team needs to set up and manage the technical systems that support the creation and maintenance of Digital Product Passports (DPPs).

- The Legal and Compliance team ensures the business stays aligned with all regulatory obligations under ESPR.

If you want to be compliant with ESPR in time, your key strategy should be to build internal awareness. Every department of your organisation must clearly understand how ESPR impacts their role and why their contribution is important to the overall compliance.

4. Engage Your Supply Chain Early:

You cannot meet ESPR requirements alone and instantly. A huge amount of the necessary Digital Product Passport (DPP) data will come from your suppliers.

Start the conversation early. A lot of your required DPP data will come from your suppliers. Communicate your future needs clearly so your suppliers will have ample time for preparations.

You should also work with your key suppliers to understand their data capabilities and address any gaps.

Invest time now in strengthening these connections. It will pay off when data reporting becomes mandatory.

5. Stay Informed & Seek Expertise:

Things move fast when it comes to compliance, and ESPR is no exception. Here’s how you can stay ahead of the curve:

- Keep an Eye on Official Updates: Make it a habit to check in on the European Commission’s announcements, especially anything about ESPR work plans, and new Delegated Acts as they’re announced.

- Stay Connected with Industry Groups: Industry associations often have the early insight and can give you practical tips that actually fit your sector.

- Considering External Help: As you get a clearer picture of what ESPR demands, take a moment to check whether your team has everything it needs. In some cases, you can consider getting some external experts or using specialist software to help with the growing complexity of data collection, validation, and DPP generation.

Conclusion: Embracing Transparency for a Sustainable Future

The Ecodesign for Sustainable Products Regulation (ESPR) marks a major shift in how the EU envisions product sustainability. It introduces ambitious new standards designed to create a true circular economy, with the Digital Product Passport (DPP) acting as a cornerstone of this vision.

For manufacturers, ESPR brings new challenges, particularly in areas like data management, technical infrastructure, and supply chain transparency. However, it also opens the door to much bigger opportunities.

Viewing ESPR as just another compliance burden misses the bigger picture. While it is true that preparing for ESPR requires effort and investment, mastering ESPR and DPP generation offers substantial opportunities:

- Ensures continued access to the lucrative EU market

- Mitigates compliance risks

- Creates a stronger brand reputation among eco-conscious consumers and partners

- Achieve Greater operational efficiency through better data management

- Elevate your organisation as a leader in the transition to a more sustainable future

Key Takeaways from this Guide

- ESPR is broad, detailed, and approaching fast. Make sure you understand the full details.

- The Digital Product Passport (DPP) is your main tool for showing you are on top of ESPR

- Delegated Acts will set the exact rules for your products—stay tuned and keep an eye out for updates.

- Getting your data collection, management, and validation in order is key if you want to stay compliant.

- Teamwork across departments and the supply chain isn’t optional—it’s the only way to make this work.

Don’t wait around for deadlines to sneak up on you!

Start assessing, planning, and pulling your teams together now.

If you fully lean into the transparency and sustainability goals behind ESPR, you’ll not only stay compliant, you’ll also build a stronger, smarter, and more competitive business for the future.

Related News

Tag

Follow us